Case Study

Assessing valve integrity using industry 4.0 techniques

SpiralData and Alexandrina Council use a non-invasive approach with internet-of-things (IoT) and machine learning (ML) to assess isolation valve integrity.

The Challenge

How to assess the integrity of isolation valves without costly and disruptive civil works.

Alexandrina Council is located on the Coorong, Lower Lakes, and Murray Mouth region. It is an environmentally significant area designated as a Wetland of International Importance in 1985. “We’re at the exit point of the Murray-Darling Basin, where it meets the ocean. It’s a pristine environment, and we have to be careful as it’s an environmentally sensitive area,” says Gary Lyons, Manager Sustainable Resources.

An immediate challenge was taking on the regional responsibility to acquire a brownfield vacuum sewer from a private property development on Hindmarsh Island. One specific issue was the assessment of isolation valves to ensure safe and efficient sewer operation. To avoid costly and disruptive civil works, Alexandrina wastewater utility wanted to utilise industry 4.0 to assess isolation valve integrity in the fastest possible time.

Data collection: SpiralData’s Industry 4.0 data collection in the field that be easily moved from asset-to-asset with data ingested into our IoT-to-AI platform.

Clockwise from top left: Hardware kit for field data collection, Alexandrina team testing isolation valves, pump station with sensors, isolation valve using microphone and accelerometer.

An IoT-to-AI Approach to Assessing Valve Integrity

Co-Design, iterations and data-first.

Rather than invest more field operators or engineering assessments at the Hindmarsh Island vacuum sewer, Alexandrina used data to inform them of the path forward. Moving quickly, they rolled out an IoT sensing network over the vacuum system and then engaged SpiralData, experts in algorithms for water asset optimisation. SpiralData worked with Alexandrina using co-design and agile principles to quickly move through: feasibility study, problem backlog, prioritised algorithm sprints, build-test-deploy, proof-of-concept then pilot, and finally, solution support and maintenance.

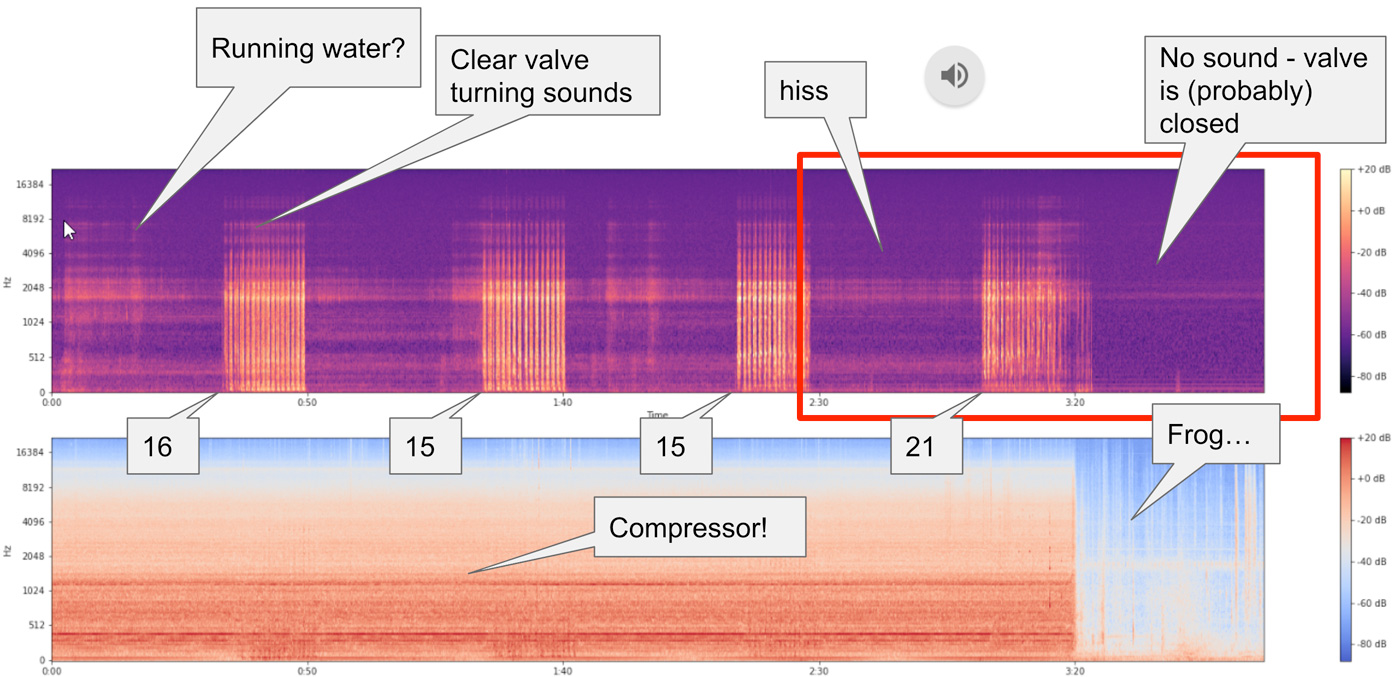

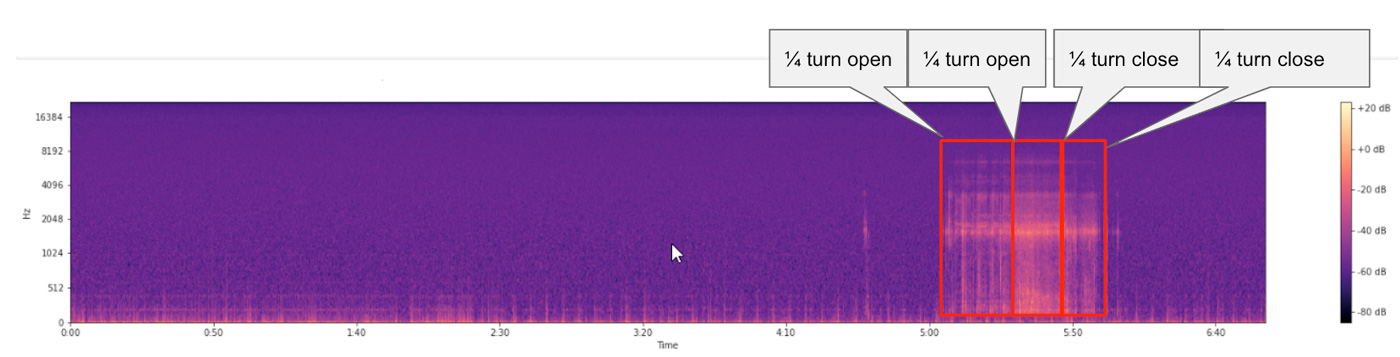

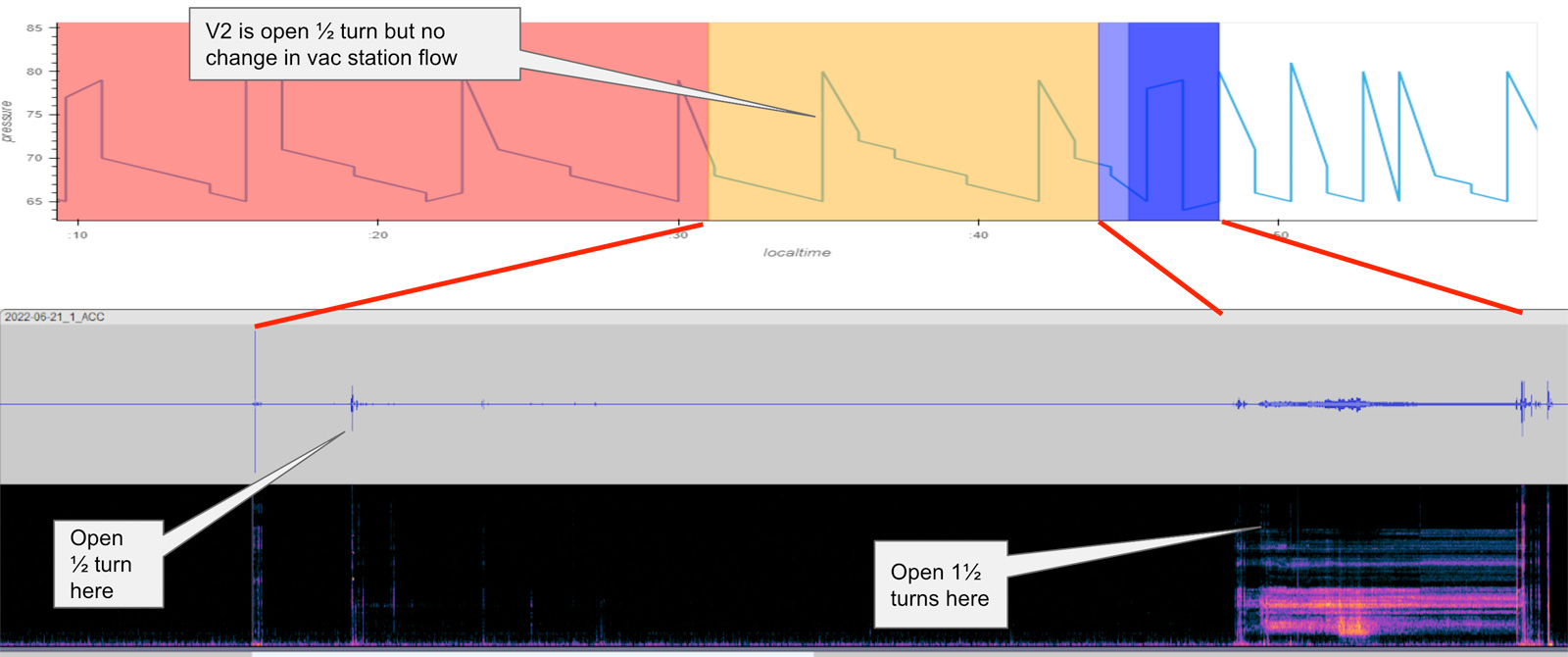

Experiments: SpiralData’s IoT-to-AI platform enabled fast, repeatable experiments to design a reliable method for assessing valve integrity.

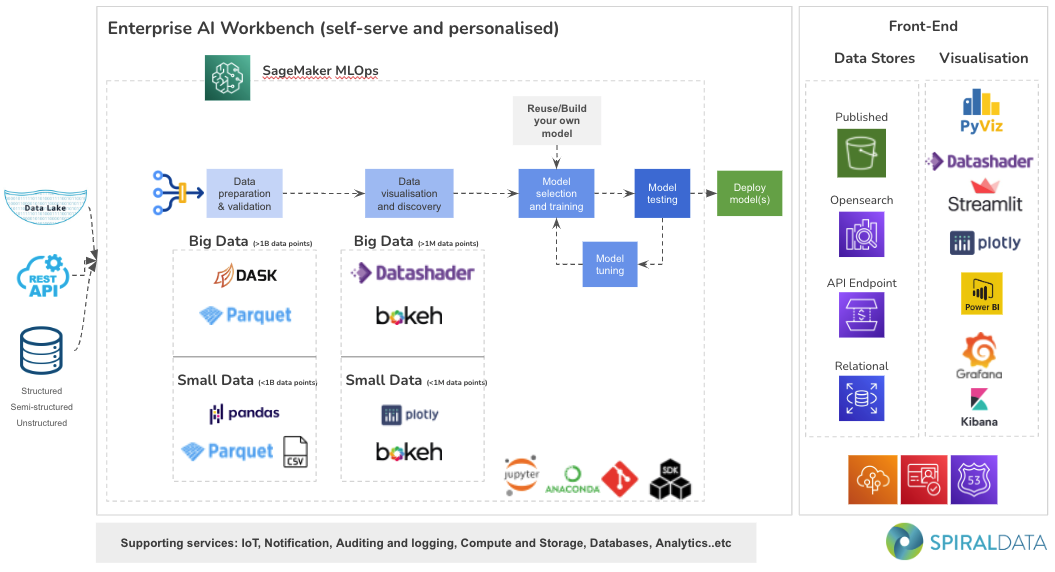

IoT-to-AI Platform

Enabling data science and machine learning teams to deliver business value

For rapid deployment of a data lake and AI workbench, SpiralData leveraged our infrastructure-as-code AI platform-as-a-service (AI PaaS.) This meant less time standing up infrastructure and more time for the Data Scientists to work with their favourite tooling to solve real-world water utility problems. This sprint involved the deployment of our AIML workbench module.

Our AI PaaS reference architecture: Our unified platform leverages the oversight and control of SageMaker on AWS and enables practitioners to self-manage with unlimited personalised tooling options. Experiments can be tracked and shared easily, enabling reproducible data science that is secure and scales.

The Results

Reliable assessment method of air ingress over buried isolation valves

Isolation valves were tested for integrity using industry 4.0 sensors and SpiralData’s IoT-to-AI platform:

No signal when valve is closed: There was no accelerometer signal when valve is closed in all cases and the number of turns correlates with signal strength. We can use this as a relative measure of flow across valves and therefore valve integrity. Note, it is not absolute measure of flow across valves because the amount of flow can vary with time (i.e. slugs of water move through the system, then it quiets down, as per normal operation.)

No costly and disruptive civil works

All valves tested have 100% integrity. There is strong evidence that when an accelerometer is measuring no signal, there is no flow across the valve. When all valves were closed we measured no flow, strongly implying that the method was reliable and therefore the leak was not in the valves.