Case Study

Predictive Maintenance for a Water Reuse Utility

City of Playford begin the journey to predictive maintenance using machine learning

The Challenge

“While we have mature monitoring capability through our SCADA system – it cannot predict pump wear. We were keen to see if the operational data managed by SAGE could have data science techniques applied by the SpiralData team to solve this for us,”

– Chris Burgess, Manager Operations, City of Playford.

City of Playford owns and operates Playford Water for the irrigation of 70 sites across Council that include both internal and external customers. Building on previous collaboration on choke prediction, SAGE Automation and SpiralData focus on the problem of predicting pump wear for City of Playford.

Recycled water is distributed through 70km of pipe via a combination of + 30 bore, distribution and jacking pumps. City of Playford Managed Aquifer Recharge schemes include four wetland sites that collect and treat stormwater, which is stored in underground aquifers and purchased by customers for irrigation purposes during summer months.

City of Playford currently has no way to predict wear across pump assets. This leads to reactive rather than proactive maintenance, refurbishment and replacement, impacting maintenance scheduling and annual budgeting. Predictive maintenance generally leads to 30-40% cost savings compared to reactive maintenance and 10-20% cost savings compared to preventive maintenance1.

Maintenance Strategies

Reactive |

Preventative |

Predictive |

|---|---|---|

| Break-to-fix, tasks performed after failure occurs | Routine tasks based on expected life and wear over time | Condition monitoring to predict failure for just-in-time tasks |

|

||

1 US Dept Energy Efficiency & Renewable Energy – https://www1.eere.energy.gov/femp/pdfs/OM_5.pdf

Technology

SpiralData uses its best-practice IoT to ML reference architecture

IoT-to-ML Architecture

- Sagemaker

- Data Lake formation

- S3

- Lambda

Algorithms

- Pandas

- Numpy

- Tensorflow

- Scikit-learn

Visualisations

- Seaborn

- Plotly Dash

- Plotly Express

- Matplotlib

Techniques

- Python, Node.js

- Data wrangling and basic calculations

- Visualisation, pairplots, heatmaps, correlations matrixes, box plots, violin plots, animation plots

- Classification algorithms

The Platform

Best-of-breed architecture for rapid device-to-algorithm insight

Data at City of Playford is recorded every 5 mins in their SCADA system. SpiralData leveraged this dataset into our IoT-to-ML reference architecture which has been proven across utilities, supply chain, advanced manufacturing and other industries. The key benefits are:

- Auto-scaling

- Secure

- Fast

- Low-cost

- Reliable

By applying the AWS well-architected framework to SpiralData’s IoT-to-ML architecture we have reduced the time-to-insight for all of our customers pursuing problems suited to machine learning.

Our in-built ML workbench allows for rapid prototyping of different algorithms for unlimited use-cases. Results can be visualised in dashboards with automated alerts able to be sent via SMS, or communication tools (Teams, Slack, etc) delivering an end-to-end solution from the device-to-the-decision-maker.

The Results

Hypothesis #1

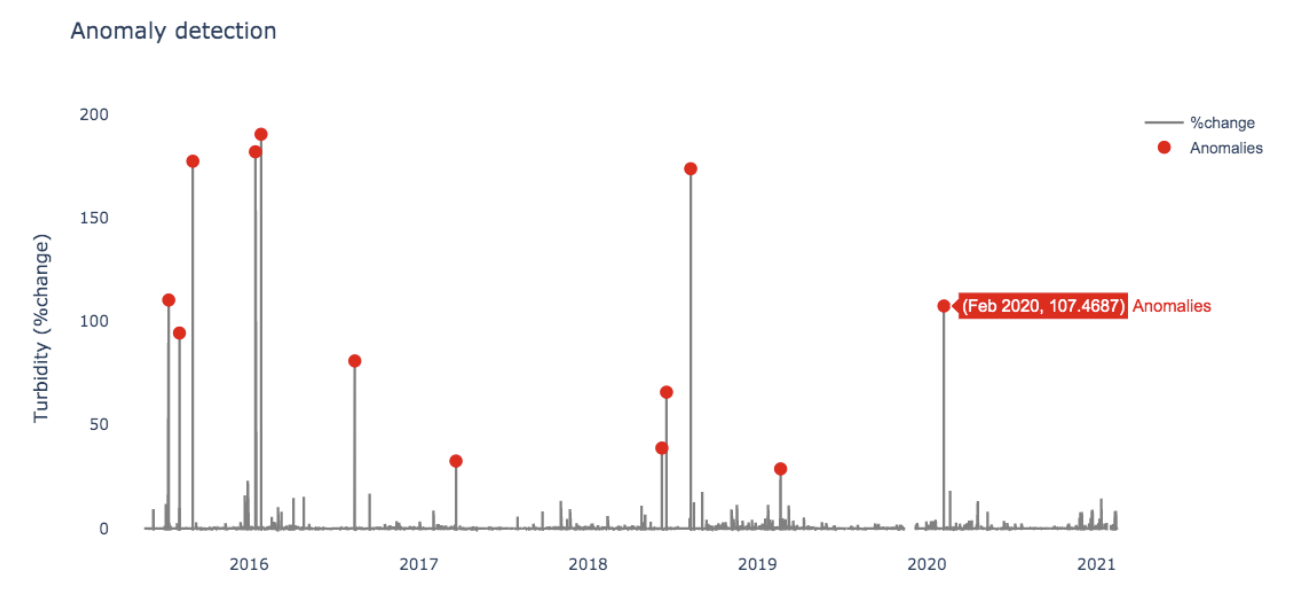

City of Playford: Increases in turbidity would be highly correlated to pump wear

Result: Turbidity was seasonal but a relatively stable pattern across multiple years while only being weakly correlated to pump performance

Outcome: While pump wear could not be strongly linked to turbidity, % changes in turbidity could be clearly identified by SpiralData’s anomaly detection algorithm

Value: By identifying in near real-time there may be a well issue, e.g. sand, discolouration, organics at one of the wells, City of Playford can deliver better product for its customers

Hypothesis #2

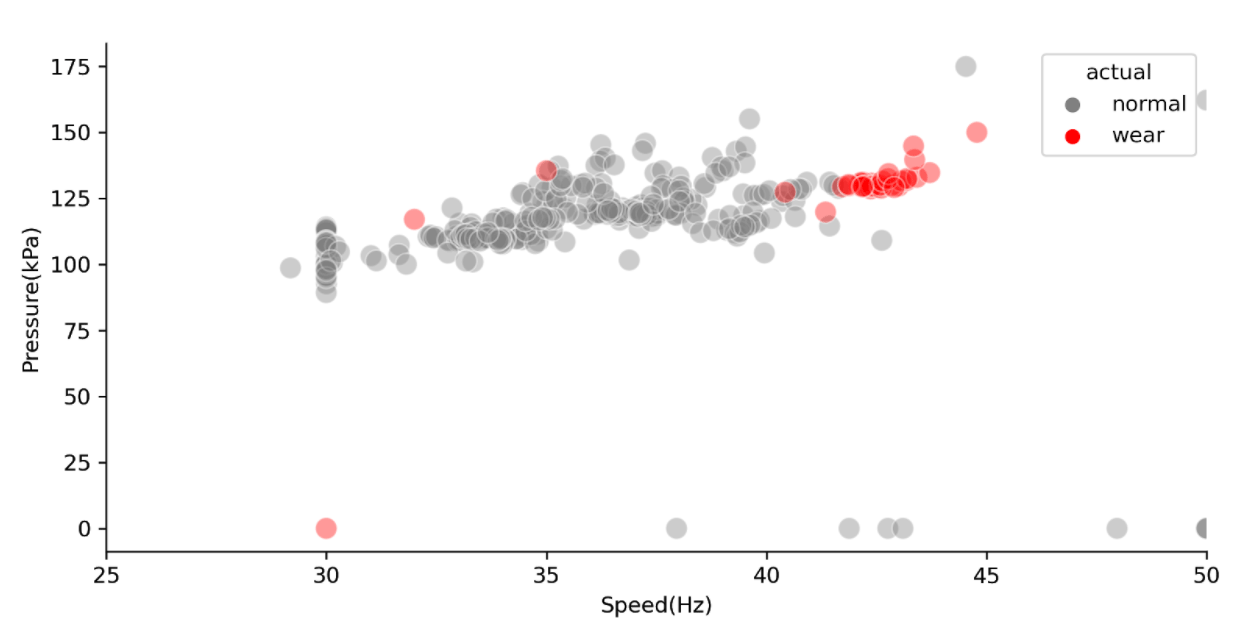

City of Playford: Changes in pump behaviour would be irregular during pump wear, ie, pressure stays constant while Hz increases.

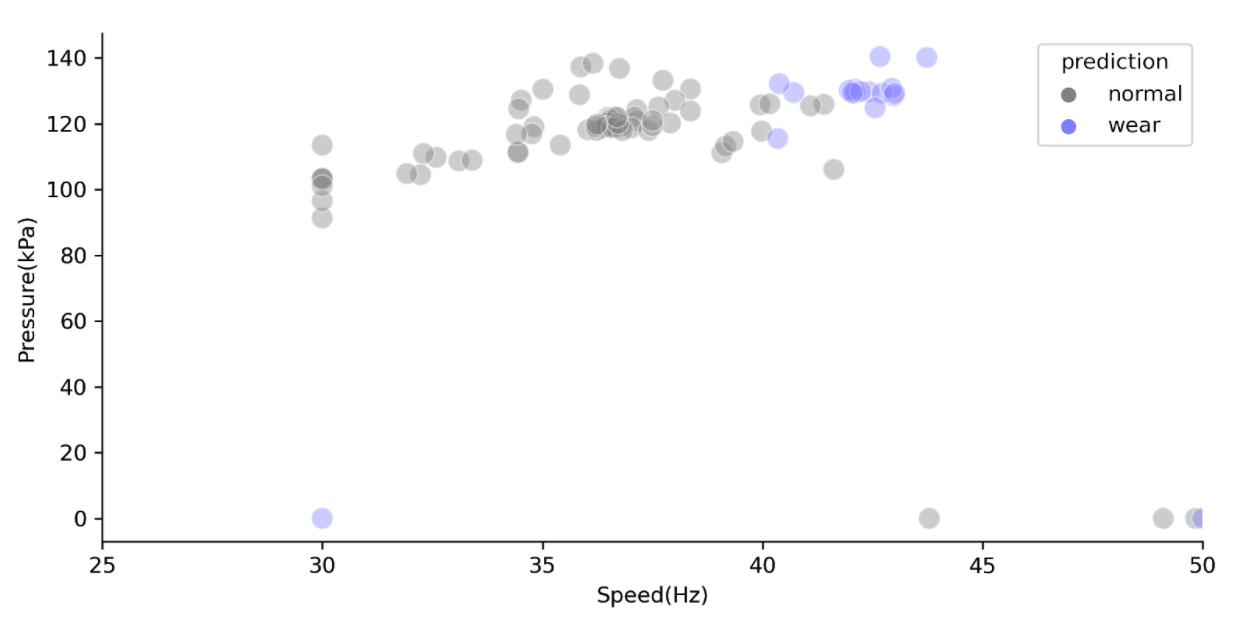

Result: Data discovery of the pump system performance revealed that key variables create clusters for separate phases, normal pump condition before wear and when a pump is worn before failure.

Outcome: SpiralData was able to train an algorithm to predict with >95% accuracy the future states of a pump to identify if it needs maintenance

Value: By identifying there may be pump wear early, City of Playford can transition to predictive maintenance, potentially saving up to 20% across its pump assets ongoing